When properly assembling a night vision device, whether it’s a PVS-14 or a dual tube set, a proper pressure test and nitrogen purge is very important.

First, a vacuum is pulled on the device. A gauge on the purge set is pumped up and left in place for a short period of time. During this time, there should be no leakage- as seen on the set by the needle falling rapidly. This is another step in confirming proper assembly and that the components are up to the task.

Then, nitrogen is then flushed into the night vision system. This is done to protect the optics from getting foggy in high humidity situations- similar to how your car windshield will fog up on the inside during inclement weather.

Another advantage of proper nitrogen purging is that if there remains any “debris in field” aka small trash inside the unit from assembly, the pressure of the purge will often show this. Pepper speck, actual spots, small lines in the tube and other tube cosmetic issues won’t move when purged, however, debris usually will. This helps the technician spot any potential problems and then the unit is disassembled and cleaned again and the whole process starts over purging the unit again. We nitrogen purge every night vision device assembled here at JRH Enterprises.

A common question regarding nitrogen purging is do you have to do it regularly? Unless the unit is damaged, disassembled, etc. purging regularly isn’t necessary. If you start to see fogging after the unit is dropped or mishandled, then certainly it’s time to get it purged again.

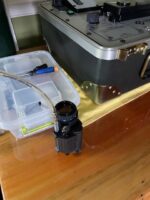

On any NV units produced by JRH Enterprises (will have a data plate on the side of the device similar to the ones in the picture below), we are happy to purge the unit for you again. This is free of charge (customer pays shipping). Email us with your system number/serial number on the side of the unit (see pic).